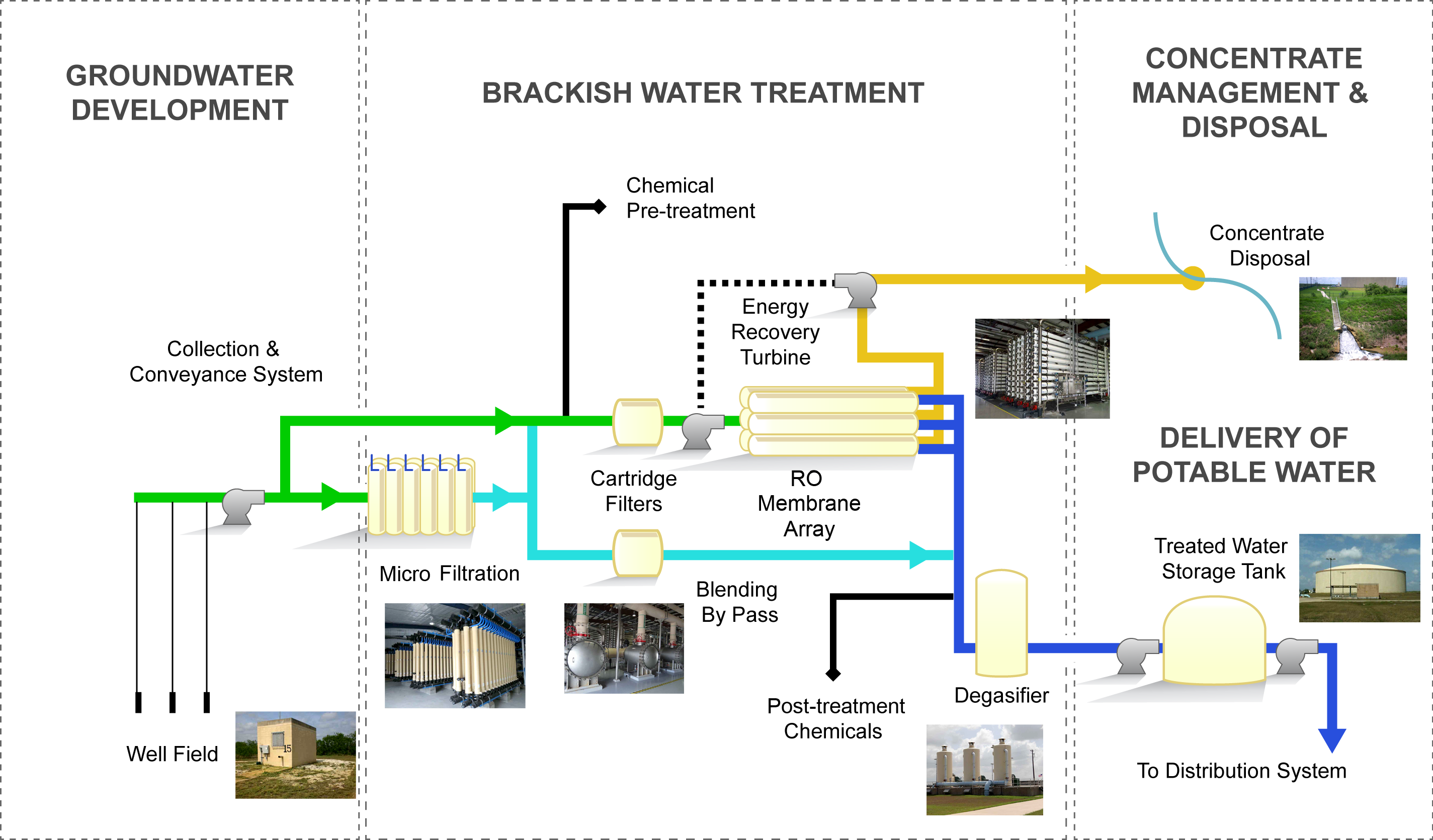

Our Treatment Process

Twenty production wells, approximately 200 to 300 feet below ground level, tap into the Rio Grande Alluvium within the Gulf Coast Aquifer. The groundwater is pumped 7.2 miles to the SRWA desalination treatment plant. The groundwater contains approximately 3,500 total dissolved solids (TDS) and reverses osmosis (RO) is membrane treatment is necessary to remove the salt to drinking water quality (less than 1,000 TDS).

Microfiltration pretreatment ahead of the RO membrane treatment process provides effective removal of iron, arsenic, and manganese, which occur naturally in the aquifer. Eight RO trains provide approximately one million gallons per day each, using a two-stage process with an overall recovery of 75%. The vessels are arranged in a 22-11 array with RO reject water from the first stage feeding into the second stage. Each vessel contains seven eight-inch brackish water RO membranes providing a nominal salt rejection of 99.6%. In 2015 the plant increased daily production capacity up to 10.0 mgd. At this capacity, SRWA saves an equivalent of approximately 11,201 acre-feet of surface water diversions per year.

The FY2025 operations & maintenance (O&M) budget is $5.9 million. Electrical and chemical costs make up the majority of O&M costs with 24% and 24%, respectively. The plant has 11 full-time employees and operates 24/7 every day of the year.

The RO membrane process produces water so clean that it is aggressive to iron and steel distribution system components, such as valves and storage tanks. The plant blends a portion of the pretreated groundwater with the RO permeate water to return minerals back into the water. The treated water is then supplemented with caustic soda and calcium chloride to further stabilize the water prior to distribution. Chlorine and liquid ammonium sulfate are used to meet minimum disinfectant residual requirements for water distribution systems.

Texas Commission on Environmental Quality (TCEQ) issued a discharge permit for concentrate disposal allowing up to 4.0 mgd of RO membrane reject water to be discharged to a drainage ditch located adjacent to plant property.